Project information

- Category: Project

- Position: Research Assistant

- Project date: September 2021 - May 2022

DREAMs

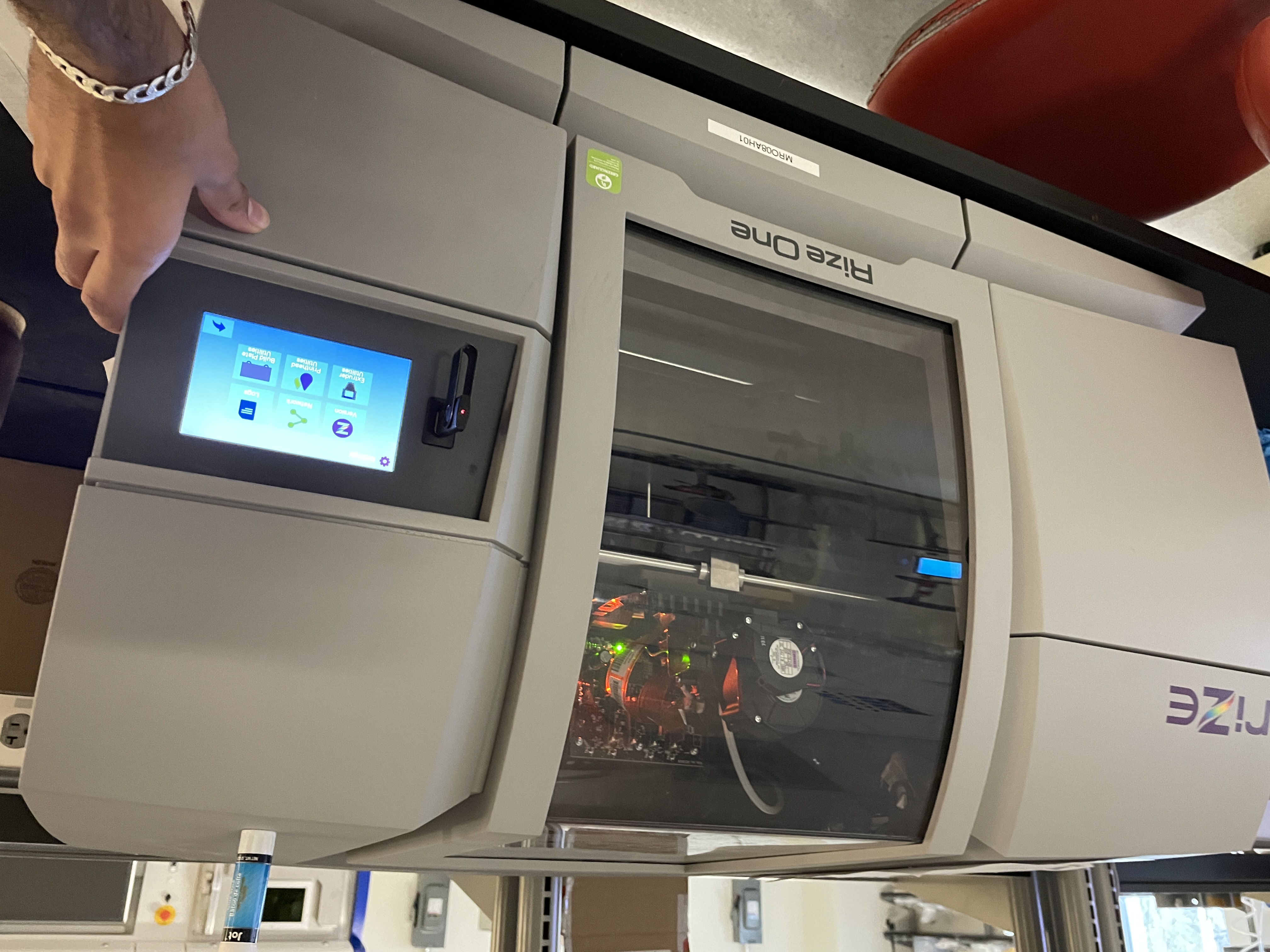

Wrote python scripts to create PNG bitmaps for each layer, customize settings,and allow for full control of piezo inkjet heads in a Rize One legacy inkjet & FDM 3D printer. Integrated a polymer that increases interlayer adhesion with FDM materials to increase the structural strength of printed parts. Designed a custom ink reservoir in SolidWorks to increase the printer’s compatibility with 3rd party polymers.

Research Area

This project worked around an additive manufacturing device that integrates FDM and inkjet allowing for complex integrated parts to be printed, which otherwise would not be possible. One major application for this technology is the use of the inkjet nozzles as a plasticizers to allow for stronger adhesion between layers. Furthermore, this technology can be expanded to electronics with the introduction of conductive inks that would allow for traces to be built into the part. This enables PCBs to be printed directly into the part, reducing the need for assembly and increasing the structural integrity of the part.

Challenges Faced

The first major challenge faced with this project involved the hardware hacking of the machine. Since

this machine was a legacy 3D printer, there was no documentation on the hardware or software. This

meant having to experiment with the proprietary file created by the slicer. After understanding the

methodology behind the file, I was able to create a python script that would allow me to create my own

instruction sets for the part.

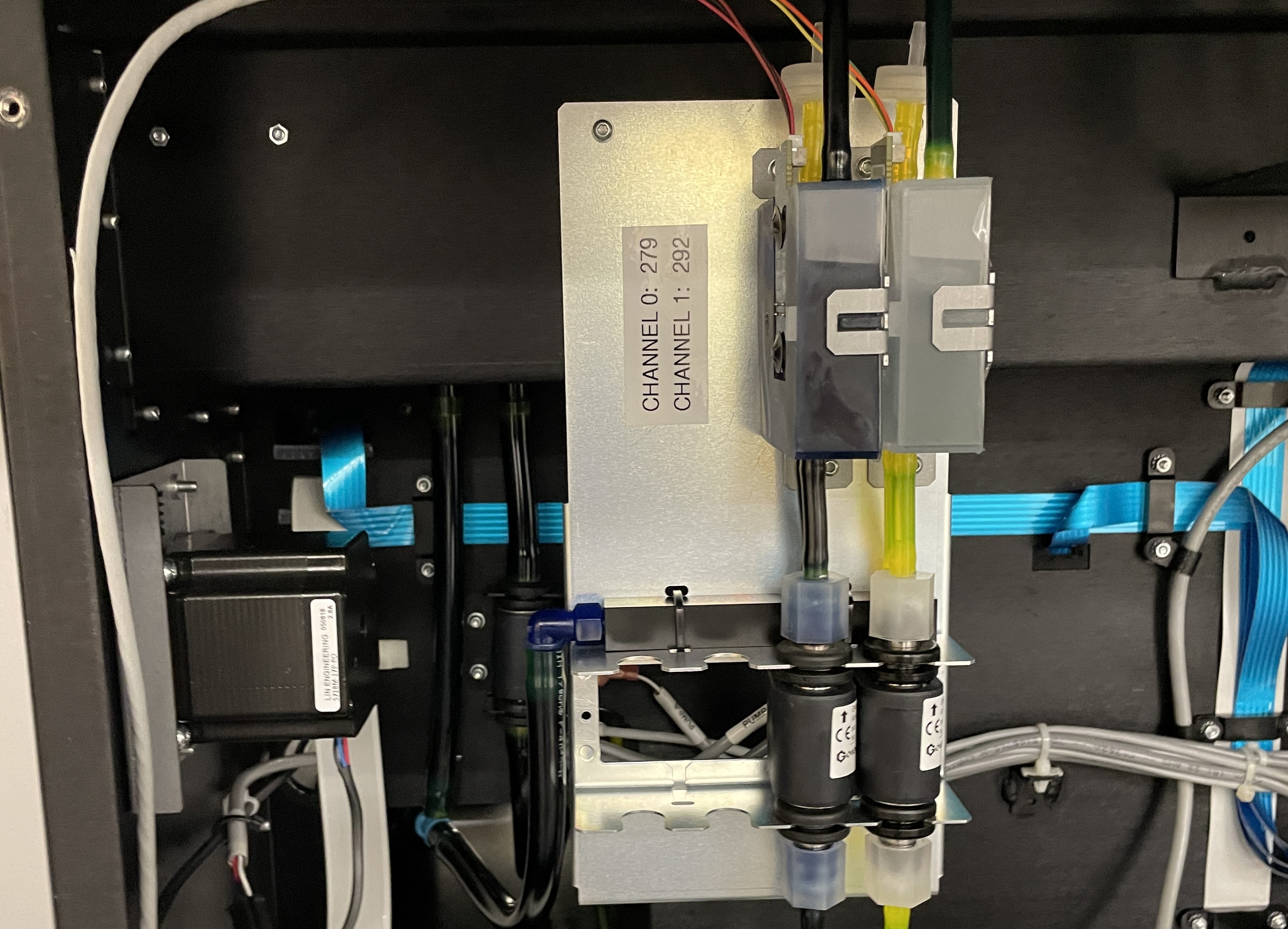

The second challenge involved the integration of the actual ink with the system. This system was

heavily locked down with chips integrated onto all disposable parts. This meant in order to use our

inks, we needed to trick the system into thinking it was using the original ink. This was done by

bypassing the ink cartridge and directly filling the ink reservoir with our ink.

The final challenge was understanding the chemical properties of the materials we utilized as an ink.

When working with some inks, we realized the surface tension was too high causing the

piezoelectric ink heads to get jammed and not push any ink out. This was solved by looking using the

Wendell and Reynolds number to determine the surface tension of the ink and how it would behave in the

system.